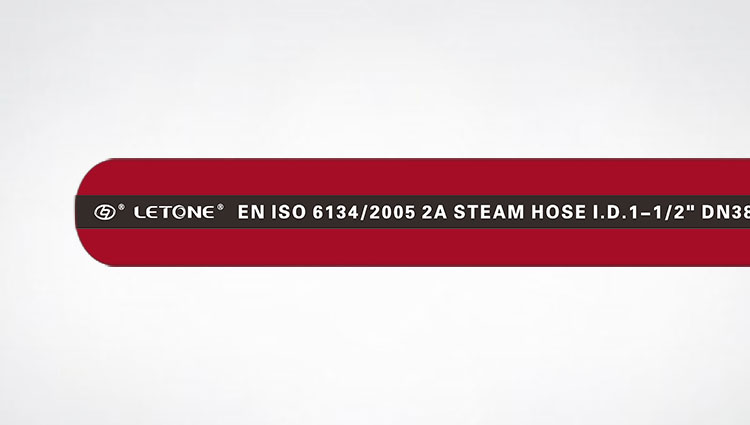

Hydraulic pump uses hose to pass hydraulic oil engineering machinery coal mine hose assembly EN856

Hydraulic pump uses hose to pass hydraulic oil. Hose assembly for engineering machinery and coal mines EN856In modern engineering machinery and coal mine opera